Your #1 Source For PTFE Wire & Cable

With our robust inventory of PTFE hook-up wire & cable, Whitmor/Wirenetics (now FDH Electronics) is the go-to source for your Mil-Spec and Aerospace requirements. From M16878/NEMA HP-3 & M22759 hook-up wire to M27500 cables, you can find all of the PTFE products you need with the excellent customer service you’ve come to expect. We also offer value-added services such as surface etching, striping, laser marking, and cut & strip for your specific program needs.

In addition to our off-the-shelf products, we have the unique ability to manufacture custom PTFE solutions for your complex cable requirements without imposing the excessive factory minimums you get from other suppliers. We offer runs as small as 100 ft, and with our Premium Expedite option, you can get what you need without the wait.

Looking for engineering help or a custom design for your application? Our engineers are standing by to tackle the tough issues so you can focus on what matters to you – providing top quality products to your customers that will perform beyond their expectations.

Contact us today for more information: Sales.Electronics@US.FDHAero.com

Did you know?

PTFE, also known by the DuPont trade name Teflon®, was accidentally discovered in 1938 by a scientist named Roy Plunkett in an attempt to create a new form of Freon refrigerant by reacting hydrochloric acid with a little known compound called tetrafluoroethylene (TFE). Plunkett discovered that instead of producing the desired gas, the TFE had polymerized into a white, flaky powder. Initially, the value of this substance wasn’t clear to Plunkett, however it came to use in World War II during the development of the Atomic Bomb. Making the bomb required scientists to handle large amounts of the caustic and toxic substance uranium hexafluoride, and PTFE-coated gaskets and liners were able to resist it’s extreme corrosive action. PTFE is inert to virtually all chemicals, and is considered one of the most slippery materials in existence. These properties have made it one of the most valuable and versatile technologies ever invented, contributing to significant advancements in areas such as aerospace, communications, electronics, industrial processes and architecture.

Today, the majority of PTFE (roughly 50% of all production) is used for aerospace and other high-performance electrical wiring applications. The superior dielectric properties of PTFE makes it an ideal insulator for wire & cable used in connector assemblies as well as printed circuit boards operating at microwave frequencies.

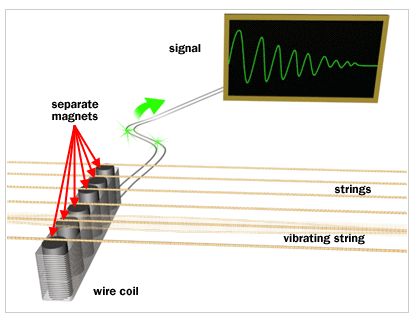

We really do share your passion for musical instruments – the electric guitar, electric bass, the tube (valve) amplifier – all tools which help us translate our innermost emotions into an audible, tangible reality.

We really do share your passion for musical instruments – the electric guitar, electric bass, the tube (valve) amplifier – all tools which help us translate our innermost emotions into an audible, tangible reality.