FDH Electronics: Your Authorized Source for Amphenol PCD Products

FDH Electronics is an authorized distributor of Amphenol PCD products, including backshells and dust caps. With extensive industry expertise, FDH Electronics provides:

-

- Immediate stock availability of Amphenol products.

- Expert technical support to assist in selecting the right backshells and dust caps.

- Fast, reliable fulfillment for aerospace, defense, and industrial applications.

Get a Quote or Place an Order for Amphenol PCD Backshells and Dust Caps Today!

For high-performance backshells, dust caps, and connector accessories, trust Amphenol PCD and FDH Electronics. Contact FDH Electronics today for expert guidance and access to a comprehensive inventory of Amphenol PCD products.

Introduction to Amphenol PCD

Amphenol PCD is a global leader in interconnect solutions, specializing in backshells, system attachments, modules, relay sockets, connectors, and cable assemblies. Amphenol PCD delivers high-quality components designed to withstand demanding environments, ensuring reliability across industries like aerospace, defense, and industrial applications.

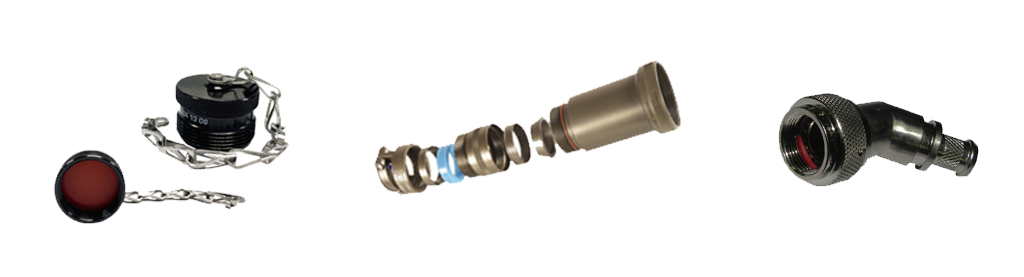

Understanding Backshells: Protection, Durability, and EMI/RFI Shielding

Backshells are essential components for protecting circular connectors by providing strain relief, environmental sealing, and EMI/RFI shielding. An estimated 70-75% of all circular connectors require a backshell, making them a critical part of any robust interconnect system.

Types of Backshells Available

Amphenol PCD backshells come in a variety of materials, finishes, and configurations:

-

- OmniLite Strain Relief: Lightweight composite for EMI/RFI shielding.

- AlumaLite: 100% aluminum, reducing weight by 50%.

- Environmental & Non-Environmental: Options with or without water sealing protection.

- Band Locks: Compact designs where EMI/RFI shielding is required

- Strain Reliefs: Ideal for lightweight cabling applications that do not require environmental protection

- Stainless Steel Strain Relief: Ideal for high-heat and high-vibration environments.

- Custom Backshells: Tailored designs for unique applications.

Dust Caps: Essential Protection for Connectors

Dust caps play a crucial role in protecting connector interfaces from dust, moisture, and contaminants when the connectors are not in use. Amphenol PCD offers both qualified parts list (QPL) and proprietary designs, ensuring superior sealing and durability.

Dust Cap Features & Options

-

- Materials: Available in aluminum, stainless steel, and composite for different weight and strength requirements.

- Lanyard Options: Expanded selections to fit various applications.

- Military-Grade & Commercial Options: MIL-DTL-38999, MIL-DTL-5015, and other specifications available.

Why Choose Amphenol PCD Backshells from FDH Electronics?

Amphenol PCD offers a wide-range of backshell solutions, including military-spec (M85049), commercial, and custom-designed backshells. Some key benefits include:

-

- Comprehensive Inventory: Large stock ensures quick availability.

- Multiple Coupling Styles & Finishes: Adapting to diverse applications.

- Custom Engineering Capabilities: Dedicated machines and engineers for tailored solutions.