In today’s on-demand market, proper inventory management is critical for success. Having the materials you need, when you need them, is one of the key factors in determining your performance as a supplier. With a heavy emphasis being placed on On-Time Delivery, being able to react to your customer’s needs quickly and effectively can have a huge impact on future business opportunities. For many companies, this means carrying additional inventory to ensure materials are on hand at all times, which can be particularly problematic for small businesses with limited cash flow or storage space.

Carrying costs can represent as much as 20% to 30% of total inventory value. Tangible costs such as storage, handling, and insuring goods are obvious, however intangibles such as opportunity cost due to reduction of cash flow, or the cost of deterioration and obsolescence of goods are often overlooked. With an increasing number of items restricted by shelf life or customer-driven product age limitations, these types of costs are more prevalent than ever.

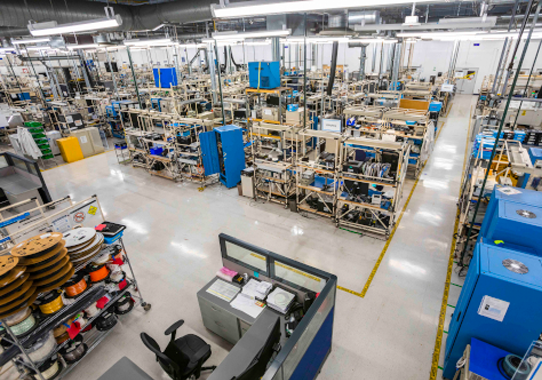

The solution? A partnership with FDH Aero, a proven leader in effective inventory management.

With a wide range of flexible Vendor Managed Inventory (VMI) options, we offer tailor-made programs that provide comprehensive solutions based on your specific business model. We don’t believe in one-size-fits-all, we focus on what makes sense for you and your customers and build from there. Whether your strategy is “just in time” delivery, on-site Vendor Inventory Management, blanket orders with scheduled ship dates, or a unique combination of several approaches – we’ve got your inventory management needs covered. With millions of dollars in inventory and same day turnaround for most orders, we have the resources to provide you with the materials you need, when you need them, every time. Some of the benefits of our VMI programs are:

- Reduced Inventory, Overstocks and Stock Shortages: Not having the right products in stock can be a big problem for you and your customers. Having too much product can be just as damaging to your bottom line – our VMI programs eliminate these issues and allow you to focus on your growth and success.

- Smaller Manufacturing Footprint: Floor and shelf space are valuable assets in your production facility, and extra inventory only uses up that space without contributing to immediate income or production needs. Additional storage not only means greater overhead costs, but that space could go toward manufacturing activities for other production floor opportunities.

- Increased Sales: Implementing a VMI can increase sales by giving you the ability to deliver your products faster than your competitors. Reduced lead times will boost the quality of customer service and foster brand loyalty. This means more returning customers and increased sales over time.

- Less Responsibility: When you reduce the financial and operational burden of managing inventory, it lowers costs, reduces admin work, allowing you to minimize inventory while simultaneously maximizing profits. Spend less time and resources on maintaining purchase records and issuing discrete orders. Let us do the work for you!

Contact your sales representative today to inquire about our VMI programs.