Your Source for Leach International’s Mil-Spec Relays

FDH Electronics, a leading global distributor and supply chain partner for the aerospace and defense industries, is proud to partner with Leach International Corp to deliver high-performance, mil-spec relay solutions to the market. This collaboration enhances FDH Electronics’ comprehensive offerings by adding Leach’s industry-leading, mission-critical relay products, renowned for their exceptional quality, durability, and performance across aerospace, defense, and high-performance industrial applications.

Leach International’s Mil-Spec Relay Product Line

Leach International has been a pioneer in power distribution since 1919, producing relays designed to meet the exacting requirements of aerospace, defense, rail, and other high-stakes industries. Their portfolio spans over 3,000 active part numbers and includes products for applications such as:

-

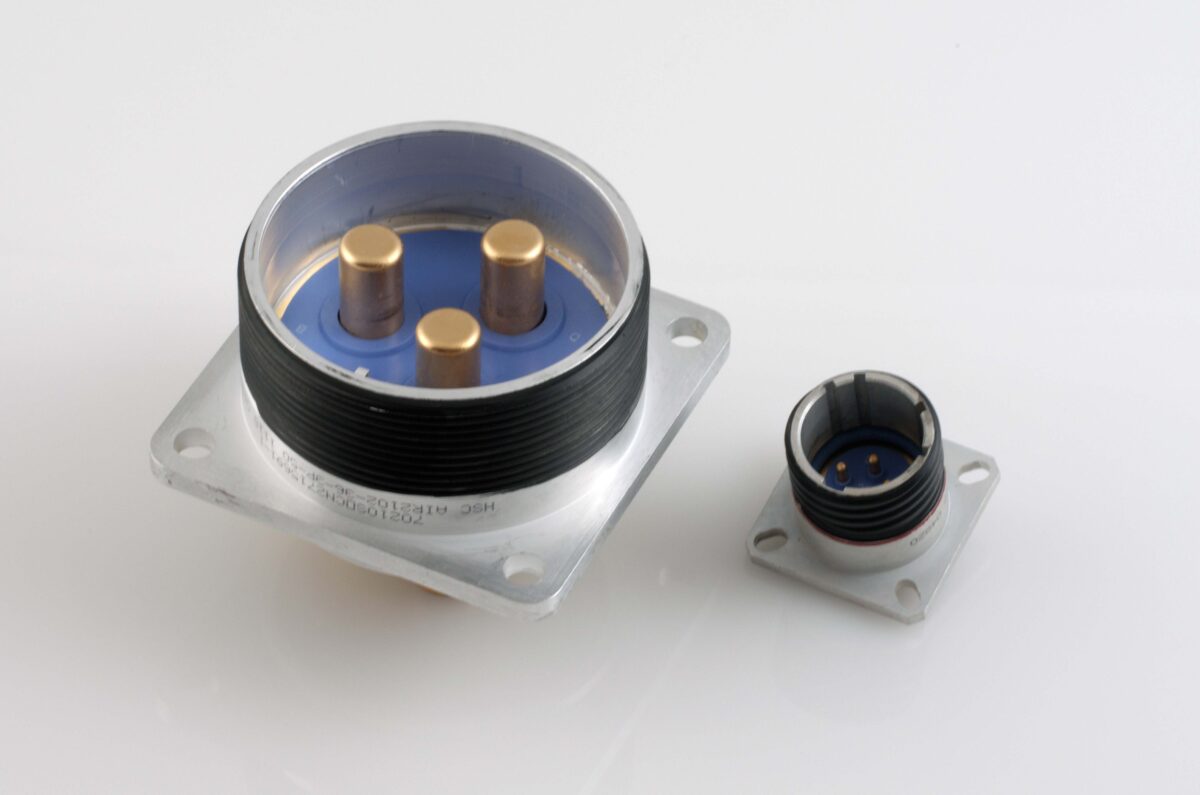

- Aerospace and Defense: Used in commercial jets, business jets, fighter jets, and space systems, Leach relays are designed to ensure dependable switching and power distribution in extreme conditions.

- Ground Vehicles and Rail: Leach’s robust relay solutions power complex industrial applications, offering reliable performance across various terrains.

- Missile and Space Applications: For space and missile systems, Leach produces hermetically sealed, vibration-resistant relays that meet the rigorous demands of aerospace-grade quality.

With Leach’s wide range of relay products, FDH Electronics is well-positioned to support a broad spectrum of customers in sourcing relays that meet specific and stringent requirements for mission-critical applications.

FDH Electronics as a Value-Added Supply Chain Partner

FDH Electronics’ role as a trusted Leach distributor goes beyond traditional distribution; it emphasizes added value and supply chain efficiency. As a value-added distributor, FDH Electronics offers streamlined procurement, inventory management, and logistics solutions that enhance the overall supply chain experience. This partnership means that aerospace and defense customers benefit from:

-

- Large Inventory: FDH Electronics is a global one-stop shop with one of the most expansive inventory levels in the industry, built on FDH Aero’s industry-leading supply chain services.

- Global Reach: With FDH Electronics’ extensive global presence, customers can access Leach products wherever they operate.

- Reliable and Consistent Supply: FDH Electronics’ deep expertise in aerospace supply chain management ensures that customers receive the products they need, when and where they need them.

- Customized Support and Solutions: FDH Electronics offers tailored solutions to meet unique project needs, helping customers optimize their supply chains and meet complex requirements.

Vertical Integration and Rigorous Testing: Leach’s Commitment to Quality

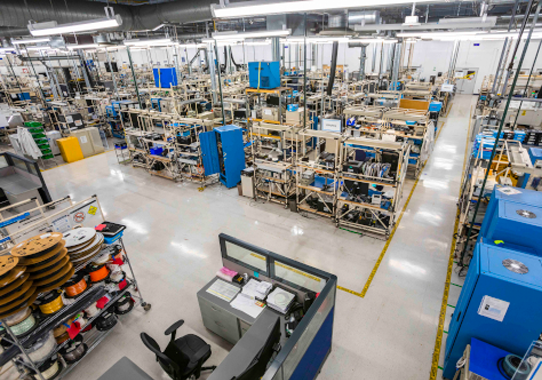

At the core of Leach International’s success is its vertically integrated manufacturing and in-house testing capabilities. By managing the full product lifecycle from design through to final assembly and testing, Leach ensures unmatched reliability. Their facilities in California and Tijuana, Mexico, allow for high-precision manufacturing processes, including:

-

- High-Performance Testing Capabilities: Testing lab power capabilities reach up to 4,000A at 28VDC, 3,000A at 115/208VAC, and 2,000A at 270VDC.

- Environmental and Functional Testing: In-house testing includes dielectric and insulation tests, leak tests, and functional assessments, meeting and often exceeding MIL-Spec standards.

- Advanced Processes for Precision and Durability: Complex processes such as high vacuum baking, glass-to-metal fusing, and coil winding are performed in-house to guarantee consistent quality.

These vertically integrated processes allow Leach to control every aspect of production, from material quality to final inspection, ensuring that every relay meets the exacting standards of aerospace and defense applications.

FDH Electronics: The Smart Choice for Leach Relay Solutions

By partnering with Leach International, FDH Electronics strengthens its position as a go-to supply chain partner in the aerospace industry. This collaboration not only broadens FDH Electronics’ product offerings but also solidifies its commitment to delivering value, reliability, and expertise at every step of the supply chain. Whether sourcing relays for commercial aircraft, military equipment, or cutting-edge space systems, customers can rely on FDH Electronics for high-quality Leach products and unparalleled support.

For companies that need mission-critical relay solutions combined with streamlined supply chain management, FDH Electronics offers the perfect combination of industry knowledge, product access, and supply chain efficiency. Through its partnership with Leach, FDH Electronics ensures that every component meets the highest standards of safety, durability, and performance—helping customers achieve their goals in even the most challenging environments.

Click Here to learn more about how FDH Electronics and Leach International are working together to elevate power distribution in aerospace.