BTC Electronic Components was recognized by Lockheed Martin Aeronautics for the second consecutive year for 100% On Time Delivery and Zero Quality Defects.

WAKE FOREST, NC, – March 2, 2015 – BTC Electronic Components (BTC) – a franchised/authorized connector distributor headquartered in Wake Forest, NC was recognized by Lockheed Martin Aeronautics for the second consecutive year for 100% On Time Delivery and Zero Quality Defects during 2014.

According to Tom Simmons, Vice President of Supply Chain Management and Alex Eksir, Vice President of Quality & Mission Success at Lockheed:

Lockheed Martin Aeronautics Company, the world’s leading designer and manufacturer of high-performance combat, air mobility, and reconnaissance & surveillance aircraft, relies heavily on our supply base to provide key and critical components required to meet our Customer obligations and support the needs of the War Fighter. BTC Electronic Components is one of those companies we depend on for products and services that meet our exacting delivery and quality standards.

In 2014, BTC Electronic Components has successfully demonstrated its commitment to excellence with 100% on-time delivery and quality of their products to Lockheed Martin Aeronautics. Your ability, workmanship, and superior standard of performance have been instrumental in supporting the commitments of Lockheed Martin to its customers.

Lockheed Martin wishes to thank BTC Electronic Components and its employees for showing continued commitment to bringing the best quality and value to our Customer and the War Fighter in 2014.

“BTC is extremelyproud to receive this recognition from Lockheed,” said Paul Moseley, President and CEO of BTC Electronic Components, “this award represents the dedication of all our employees to ensure we are continually improving the service we provide to all of our customers.”

ABOUT BTC

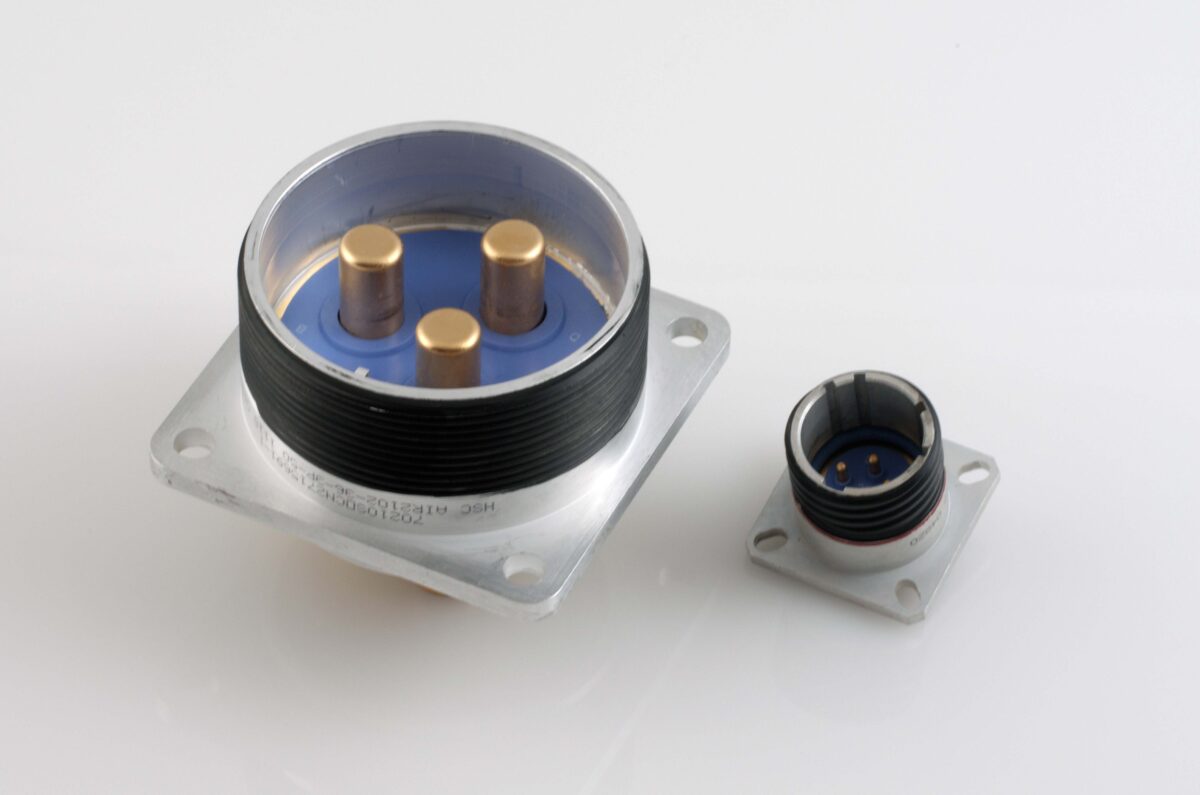

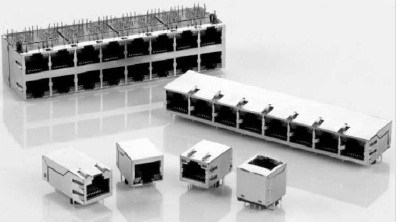

BTC Electronic Components, Inc. is a franchised/authorized, stocking and value-added assembly supplier of connectors, backshells, interconnect accessories and manufacturer of cable assemblies and wire harnesses. Founded in 1980, BTC has been designing and supplying interconnect solutions to the aerospace, military, medical, industrial, energy and transportation industries for more than 35 years. BTC’s product expertise, commitment to quality and vast buying knowledge provides a unique customer experience that is unmatched in the industry. Certifications: AS9100 Rev C, ISO9001:2008, MIL-STD-790, ITAR Registered, SAE AS5553 Compliant, Small Business.